A new mass timber product in North America

By Lucas Epp

Introduction

Use of mass timber as a structural system is on the rise in North America. Replacing traditional structural systems such as concrete and steel, these prefabricated solid wood panels create a construction method that is fast, clean, and sustainable – not to mention aesthetically pleasing. With recent projects like the 220,000-sq.ft. T3 office buildings in Minneapolis and Atlanta, the cost-competitiveness of mass timber is now being shown at scale.

Dowel Laminated Timber (DLT), known as dübelholz (literally “dowelled wood”) in Europe, is a structurally efficient and economic mass timber panel which can be used for floor, wall, and roof structures. In many ways, it is similar to Nail Laminated Timber (NLT), but without the nails. DLT panels are the only 100 per cent mass timber product – in concept they involve no glue or nails.

History of Mass Timber

Before describing DLT in detail, it is important to understand NLT – the oldest mass timber product, which has been in use in heavy timber structures for over 150 years. Examples exist in the warehouse districts of many cities. Large industrial buildings like the 500,000-sq.ft., eight-story Butler Building (Minneapolis, built in 1906) used solid-sawn posts and beams with NLT floor panels to create a robust structural frame.

NLT is created from dimensional lumber stacked on edge – nominal 3″, 4″, 6″, 8″, 10″, or 12″ boards which are laminated and fastened together with nails. Plywood or OSB sheathing is often added to the top side to provide a structural diaphragm. This system became prevalent, leading the National Lumber Manufacturers Association to create Heavy Timber Mill Construction Buildings in 1916, an illustrated guide to structural and fire detailing of these heavy timber structures.

Heavy timber construction fell out of main stream use with the industrial revolution and the rise of steel and concrete as primary building materials.

However, this is starting to change as the construction industry realizes the importance of sustainable construction. Wood is the only primary structural material that is renewable and grows naturally.

Julius Natterer, a famous Swiss timber engineer, re-introduced the concept of NLT (known as brettstapel, literally “stacked elements”) to Europe in the 1970s. Natterer saw NLT as a mass timber product that could be produced by anyone, and encouraged manufacturing throughout Europe. However, the nails inside NLT meant that CNC machining of these panels was impossible, and manufacture by hand was laborious.

History of Dowel Laminated Timber

In the early 1990s, DLT/dübelholz was developed by Alois Tschopp (Tschopp Holzbau) with Pirmin Jung in Switzerland. They saw this product as a superior product to NLT/brettstapel in every way – it used only wood, it was CNC machinable, and production of the panel was possible with automated machinery. They proceeded to create the first automated machinery line for DLT.

In Europe, DLT is a well-known and well used mass timber product. Although both products were developed around the same time, CLT has developed a larger market share in Europe, as the big glulam manufacturers saw CLT as a glued product which would be easy to expand into. DLT remained the realm of smaller manufacturers – the largest manufacturer produces around 15,000m3/year. Interestingly however DLT is often cheaper than CLT in Europe, and is gaining more interest, due to DLT being 100 per cent wood.

Recent larger and taller wood buildings in Europe have used DLT as floor and wall panels (E3, Berlin). There are more than 15 manufacturers of DLT in Europe, primarily located in Switzerland, Germany and Austria.

DLT in North America

In 2017, StructureCraft installed the first DLT production plant in North America. This high capacity, fully automated DLT machinery line is the fastest and largest capacity worldwide, and is intended to introduce a new cost-competitive mass timber product to the rapidly growing market in North America.

DLT Manufacturing

DLT panels are made from softwood lumber boards stacked like the boards of NLT, but friction-fit together with hardwood dowels instead of nails. The dowels hold each board side-by-side, forming a stiffer and stronger connection than the nails in NLT. Each board lamination in a DLT panel is finger-jointed, creating a stiffer and stronger panel than NLT as it eliminates the board splices and butt-joints which are characteristic of NLT.

DLT panels may be processed using CNC machinery, unlike NLT panels (due to the nails). This creates a high tolerance panel which can also contain pre-integrated electrical conduit and other service runs.

Panelized Building Elements

DLT panels are prefabricated in sizes of up to 12 feet wide and 60 feet long. Each panel is put through a panel planer to ensure a dimensionally accurate and planed surface. Prefabricated panels can be factory finished with sealers or stains.

Finish and Geometric Possibilities

DLT is a versatile product, and naturally lends itself to creating unique aesthetics on the exposed face of the panel. Each of the laminations are run through a profile molder, meaning many different profiles are achievable, from notches and reveals to flowing curves.

Curved DLT panels can be created by milling custom profiles into each lamination, creating a flexible panel which, like an accordion, can accommodate curves perpendicular to the span direction of the panel. The radius for these curves is limited only by the bending stiffness of the dowels, which are located centrally in the panel. These panels are created initially flat and then curved into shape on site.

Fluted panels (e.g. 2×4-2×6-2×4) can create a unique soffit aesthetic if exposed, and allow the running of electrical conduits or sprinklers in the gaps.

Unique to DLT as a mass timber product, acoustic profiles can be integrated directly into the bottom surface of a panel. This can help a designer achieve acoustic objectives while keeping the wood exposed and allowing for a wide variety of surface finishes.

Any wood species incorporated in the International Building Code (IBC) and referenced National Design Specification (NDS) for Wood Construction can be used in DLT, as only specified strength and stiffness for each lamination is required. Full-scale panel testing is not required to determine structural performance – a significant advantage to DLT as a product.

Structural Performance

As a floor or roof deck, DLT is a highly efficient structural panel. Similar to NLT or GLT (glulam on flat), all of the wood fiber runs in the direction of the span. This provides the most efficient use of material for floor and roof systems which are typically one-way spanning between beams or walls.

From a structural perspective, each individual lamination spans between supports, meaning calculation of the panel stiffness and capacity is simple. The structural design of each lamination in a panel is covered by CSA O86 and the NDS and applicable grading rules. Structurally finger-jointed lumber is used for spans longer than 20 feet, meaning no reduction in strength or stiffness is required for longer panels. This is a big advantage over traditional NLT where butt joints in laminations require a 20 to 30 per cent reduction in panel strength and stiffness (refer to Nail Laminated Timber Design Guide, Table 4.1 and IBC 2015 2306.1.4).

The Uniform Building Code (predecessor to the IBC) has recognized laminated decking since 1927, and the NBC since its first publication in 1941. The requirement for minimum fastening of the boards together ensures that the panel acts as an element and not individual boards. The 3/4″ diameter hardwood dowels in DLT can create the same interlayer shear capacity between boards as the original 20 penny nail requirement specified in the IBC.

Machine stress rated lumber can be used to increase strength and stiffness of the panel.

Diaphragms and Shear Walls

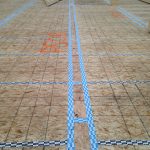

Plywood or OSB sheathing atop the panel gives shear capacity to DLT panels for use as structural diaphragms in floors and walls. The sheathing also allows for simple nailed connections between panels with strips of plywood. The shear capacity of the sheathing applied overtop the DLT panels can be calculated like a typical nailed plywood diaphragm per CSA O86 11.5 or Special Design Provisions for Wind and Seismic (SDPWS) 4.2.7.1.

Bearing Walls

DLT panels can be used as structural bearing walls with the DLT exposed on both sides, or sheathed one or both sides as a shear wall.

Two-Way Spans

Smaller two-way spans or weak-axis cantilevers (up to two- to three-foot cantilevers or four- to six-foot simple spans) can be achieved in DLT panels by using screw reinforcement inside the panel. Screw reinforcement for a weak-axis cantilever can be designed using a strut-and-tie truss analogy to design angled shear and compression screws, and using the plywood sheathing as a tension flange.

Larger minor axis cantilevers can be achieved using steel or wood outriggers set atop or notched into the top of the panel.

Detailing for Moisture

When detailing DLT panels, designers need to account for moisture movement – wood expands perpendicular to grain when as moisture content increases. Incorporation of small gaps between panels deals effectively with this issue. The T3 Minneapolis structure had a floor plate which was 220 feet wide, and which experienced both snow and rain during winter construction. The gap between panels effectively dealt with expansion of the panels during construction, and there were no issues with moisture damage or remedial works required. The key is in detailing for the movement, and letting panels dry out after they get wet.

Use of OSB sheathing with a pre-applied moisture-resistant top coating and taped joints is a newer solution to this issue. Along with providing a path for the water to move off the floor plate, this strategy provides significant protection from moisture, and greatly reduces expansion of the panels.

If a gap is provided between panels, it can be filled in afterwards with lumber, or retained to create a visual delineation between panels – as it was on the T3 building. From a fire design perspective, the gap between panels is not an issue if a continuous topping layer or plywood spline is provided. Similar to a plywood spline between CLT panels, this continuous layer prevents air movement between floors, thus ensuring char development remains uni-directional (NLT Guide 3.3.2). The local authority having jurisdiction (AHJ) for the T3 building accepted permanent gaps between NLT panels for this reason.

Fire Performance

DLT can be used in all types of combustible construction. From a fire perspective, DLT behaves the same or better than NLT.

Both the National Building Code of Canada (NBCC) and the IBC recognize NLT and provide guidance for both structural and fire design. No product-specific standard is required, as the structural design of each lamination element is covered by the building codes. It is resistant to fire, and has long met the requirements of heavy timber in North American building codes. NLT can be used in all types of combustible construction.

The fire resistance of mass timber panels is now widely proven – the char developed during a fire creates a self-protection layer. Research recently completed by FPInnovations showed that a 2 x 8 NLT floor panel with concrete topping can achieve a three-hour fire resistance rating under full load (Osborne, 2015).

The inherent fire performance of mass timber removes the need for intumescent coatings and dropped ceilings that would be required for a steel structure, allowing the wood to be exposed as a permanent soffit.

Acoustics

As with all mass timber systems, it is important to address acoustic separation between mass timber walls and floors, which can be achieved through appropriate detailing. Acoustic mat should be used in floor buildups with no dropped ceiling.

Vibration and

Timber-Concrete Composites with DLT

The stiffness of mass timber panels is important in long-span floor systems, and as can be seen in Table 1, consideration of floor vibrations often govern the required panel thickness.

A concrete topping is often required for acoustic performance, and this topping can be made composite with DLT panels to increase the panel stiffness. In Europe, many different techniques of creating composite action between the DLT and the concrete topping are used, including:

• Fully threaded screws inclined in the direction of the shear flow

• Milled notches in the DLT panel, continuous perpendicular to the direction of the span

• Use of fluted DLT, with the flutes turned up so the concrete topping flows between the higher laminations

SUMMARY

Dowel Laminated Timber takes mass timber construction one step further to create a 100 per cent wood panel which can be CNC machined and incorporate acoustic treatment into an exposed wood soffit. Due to its efficiency, aesthetics, and cost effectiveness, DLT will help lead the push towards wood construction.

DLT also extends the range of mass timber options available in North America, and supports the trend towards prefabrication as the future of building construction.

References

• Binational Softwood Lumber Council. 2017.

Nail Laminated Timber – U.S. and Canadian Design and Construction Guide v1.0.

• E3 Berlin, www.proholz.at/zuschnitt/33/lueckenfueller-mit-distanz

• Osborne, Linday (FPInnovations). 2015.

“Fire Resistance of Long Span Composite

Wood-Concrete Floor Systems”

Lucas Epp, P.Eng., leads the engineering department at StructureCraft and has also co-authored industry guidelines including the recently published NLT Design and Construction Guide. He can be reached at lepp@structurecraft.com or (604) 313-2526.