A living laboratory to demonstrate seismic resilience

Paul Fast, P.Eng., Struct. Eng, P.E., FIStructE, IngKH (Germany)

Tobias Fast, P.Eng., P.E., M.A.Sc.

After spending most of its history in a two-storey, custom-built office block in Vancouver, B.C., Fast + Epp’s rapid growth over the last few years sparked the decision to seek a new location. In view of the ever-increasing migration of people to the suburbs of Vancouver for lower housing costs, moving the office closer to a rapid transit nexus would ease transportation challenges for the firm’s staff, so the company purchased a 12×37-m corner site a short walk from what promises to become one of Vancouver’s busiest transportation hubs (where the SkyTrain will connect to the Broadway Subway, which started construction this year).

The Fast + Epp Home Office is scheduled for completion by the end of this year. Along with accommodating up to 80 employees, the building features a dedicated “living laboratory” to enable in-house destructive testing of connectors, 3D printing, prototype and mockup preparation, software development and material sample displays – which are all part of the firm’s Concept Lab initiatives that have resulted in products including their Concept app and Timber Bay Design Tool.

With the firm’s involvement in high-profile mass timber projects such as the 3-million-sq.ft. Walmart Home Office campus in Bentonville, Arkansas, and 10-storey Arbour at George Brown College in Toronto – along with a desire to push the design envelope on projects – Fast + Epp wanted to “walk the talk” when presented with the challenge of designing its headquarters. Considering Vancouver’s location in a notoriously active seismic region, part of the “Ring of Fire,” the new building also presented a prime opportunity to showcase and test contemporary hybrid mass timber office construction coupled with state-of-the-art seismic technology.

Advances in Seismic Engineering

The need for robust structural systems to resist a building’s inertial forces induced by seismic ground motions has been pushed to the forefront of engineering design and building codes by the widespread damage witnessed in several notable earthquakes of recent history, starting with Northridge, California (1994) and Kobe, Japan (1995). The devastation to supposedly modern, state-of-the-art structures seen in these quakes intensified the demand for research and development in the field of seismic engineering.

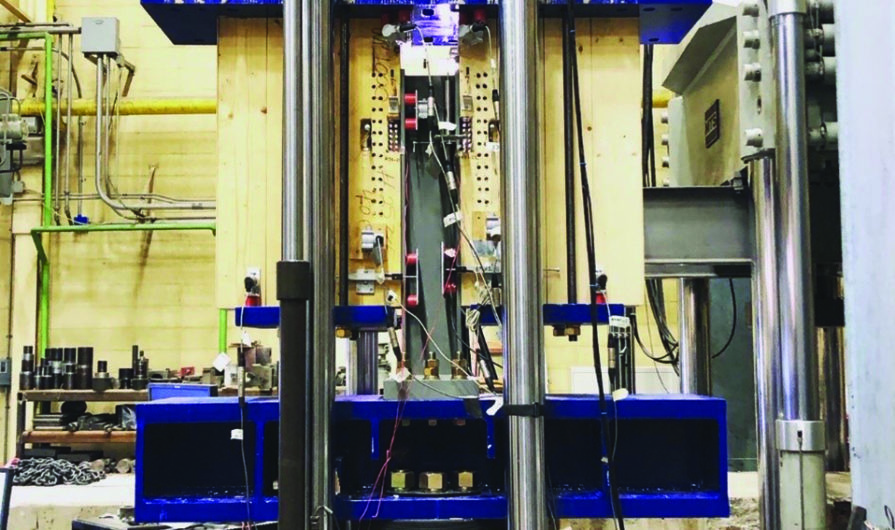

Mass timber applications are included among the engineering advances developed for building in high seismic zones. Timber has an excellent strength-to-weight ratio when compared to traditional construction materials, so its use in lateral force resisting systems is not out of place. CLT provides excellent in-plane shear capacity, making an ideal candidate for shear walls and diaphragms, while glulam sections can be used as beams, columns and diagonals in a braced bay assembly. Fast + Epp has participated in numerous research initiatives to test various mass timber lateral systems including novel energy-dissipating CLT shear wall hold-downs and CLT balloon-frame shear wall detailing. Lessons learned in the lab have resulted in several real-life applications of mass timber lateral systems, including multi-storey structures in both Vancouver and Toronto.

Currently, many buildings are designed with ductile earthquake-resisting lateral elements that experience large and permanent plastic deformation and damage during an extreme event. As demonstrated during the 2011 Christchurch earthquake in New Zealand, many buildings became uninhabitable due to ongoing safety concerns arising from permanent damage. Fortuitously, a presentation by Dr. Pierre Quenneville from the University of Auckland during Fast + Epp’s design investigations led the design team to a solution that will be implemented for the first time in North America.

Key to modern seismic design philosophy is the concept of energy dissipation. Acceleration of the ground beneath a building creates a similar acceleration of the building mass above, resulting in lateral forces being imparted to the building’s structural system. In high seismic regions, these forces are understandably large and will govern the size and spacing of the primary structural elements; to reduce the seismic demand on a structure, a building can be designed to dissipate energy. Typically, this is achieved through yielding of steel elements (rebar yielding within concrete shear walls or steel connector yielding), as the material exhibits exceptional ability to undergo deformation without losing (and in some cases, actually increasing) strength. Steel connectors are often used to provide energy dissipation in timber lateral systems for the same reasons.

For its first application in North America, Tectonus devices are used at the bases of the building’s CLT shear walls. Manufactured in New Zealand, these self-centering, spring-loaded metal brackets dissipate energy through friction and provide a restoring force to ensure the building has no permanent drift after an earthquake, and providing immediate post-disaster safety of the structure. The device -consists of -serrated steel side plates which are clamped to a central serrated plate with through-bolts and spring-loaded washers. As the shear wall rocks back and forth under seismic loading, the gapped top and bottom central plates travel through the saw-tooth profile, dissipating seismic energy through friction and compressing concave washers to store up spring energy which provides the restoring force.

Building Design &

Construction Process

While having to shoehorn almost 16,150 sq.ft. of permissible area into a tight site was not without significant planning -challenges, the design collaboration between –

Fast + Epp and f2a architecture yielded a four-storey building with generous daylighting at the north, south and west sides, ample balcony space arising from setbacks at the north and south ends of the fourth floor, a two-storey central atrium connecting the third and fourth floors, and a single-storey underground parking level. Given the site constraints and minimal laydown area, it was critical to prefabricate as many -structural components as possible to facilitate a short, seamless erection period – one of the primary advantages of mass timber construction.

Many prefabricated timber and hybrid timber-steel panel options were considered for the floor construction, particularly solutions that would integrate and conceal mechanical and electrical components within the prefabricated assembly in a shop-controlled environment. In this instance, however, simplicity won out over complexity, and Fast + Epp elected to use glulam beams clear-spanning 12 m at 3 m spacing, that support CLT floor panels. In the spirit of the building becoming a living laboratory, Fast + Epp reduced the size of the glulam beams to a 608 mm depth, satisfying safety requirements while pushing the limits on vibration performance. Typically, a disconnect between theoretical and real-life vibration characteristics is found; this was the firm’s opportunity to carry out exhaustive testing to better understand these differences. A vibration testing program using accelerometers was established, knowing that there was a Plan B in place in the event performance was unsatisfactory.

The floor panels consist of three-ply CLT panels with a total thickness of

105 mm at levels two, three and four, and 87 mm at the roof. A non-composite

50 mm-thick concrete topping layer and

10 mm-thick acoustic mat is added on top of the CLT. Fire resistance of up to two hours is achieved by reinforcing the concrete topping and relying on the contribution of both CLT and topping. The underside of the CLT panels remains exposed in most of the desk areas, with mechanical ducts, sprinkler lines and electrical conduits strategically located to ensure a clean, tidy ceiling expression.

At one end, the glulam beams are supported on steel columns. While glulam columns also were contemplated, larger sizes were required to achieve up to a two-hour fire rating at the ground floor; hence, intumescent-coated, round 168 mm-diameter steel columns were preferred. The steel not only lends a lighter feel to the space but also provides contrast to the generous amount of exposed timber surfaces. The opposite ends of the glulam beams are supported on glulam columns connected to a five-ply CLT firewall at the zero-lot line.

Lateral resistance to wind and seismic loading is provided by the 33 m-long CLT firewall in the north-south direction. The shorter east-west direction loading is resisted by a combination of four seven-ply CLT stair and elevator core walls, as well as a single steel brace frame. Due to constraints relating to door openings at the northern stair core, the steel brace is required in lieu of an additional CLT wall.

The superstructure installation, which was completed this summer, highlighted the speed and efficiency of this construction typology as the four-storey structure was erected over a period of only four weeks. A single mobile crane and a crew of five carpenters were mobilized to install the mass timber structure on a site that had virtually no lay-down space and limited access, at a busy city intersection. Many building elements were prefabricated to facilitate quick installation: The Tectonus elements were embedded in the CLT shear walls, moisture barriers and insulation were preinstalled on all CLT exterior walls, and service penetrations through glulam beams were CNC-cut in the shop. Additionally, a 3D clash detection model, including all structural and glazing components, was built in Rhino3D to reduce potential site conflicts and facilitate the high level of prefabrication. To simplify construction and reduce costs, an -aggressive approach to moisture management was adopted by preapplying a temporary moisture membrane to the roof panels only, with the understanding that the structure would only be exposed to rainy weather for a few short days during sunny summer weather. Some additional sanding and finishing will be required; however, this is often the case for exposed timber buildings.

The building also features electrochromic glass, a glazing technology that enables automatic tinting of windows based on roof-mounted weather sensors, substantially reducing cooling loads during warm summer periods. Each windowpane also can be manually controlled via a -smartphone, and video imagery can be displayed on the inside face of the glass without obscuring the view from outside.

The Living Lab Takes Shape

A willingness to treat the office headquarters as a workshop for all manner of building science topics has led this project to become a living laboratory. As the number of tests increased throughout the construction of the building, it became apparent that this type of engineering and building science testing could become a much more integrated part of the

Fast + Epp business, resulting in the development of the 5,000-sq.ft. Concept Lab space to house research and development related to various aspects of mass timber construction.

For example, floor vibration is a complex issue that deserves close attention in mass timber construction due to the lighter floor build-up. Many variables affect floor vibration, including occupant perception, structural connections, office furniture and partitions, floor build-up and more, making it difficult to gain an accurate understanding of what the true in-situ performance of a system will be. To assess the various factors, Fast + Epp conducted an extensive sensitivity study including using accelerometers to test full-scale mock-ups and in-situ structure during separate construction stages (bare wood floor, wood floor with topping and wood floor with full interiors fit-out).

Preliminary results indicate that the economically designed lightweight floor performs much better once the vibration-mitigating factors are taken into account including actual connection stiffness, concrete topping stiffness and the testing of the system as a whole, rather than just a localized three-bay mock-up assembly. Should there be any localized areas with unacceptable vibration performance following final interior fit-out, tuned mass dampers consisting of steel plates will be installed to mitigate against this.

Acoustic testing will continue to assess the floor assembly, which consists of an exposed CLT soffit, 10 mm acoustic membrane, concrete topping and carpeting. Sensors also are being installed along the western exposure CLT feature wall to test the thermal performance of the building envelope system. In addition to ongoing vibration testing and analysis, the CLT wall structure also will undergo thermal performance testing.

While the process and implementation of new ideas and technologies simulate an experiment, this project fits well within

Fast + Epp’s culture, values and “fresh thinking” philosophy to push the design envelope.